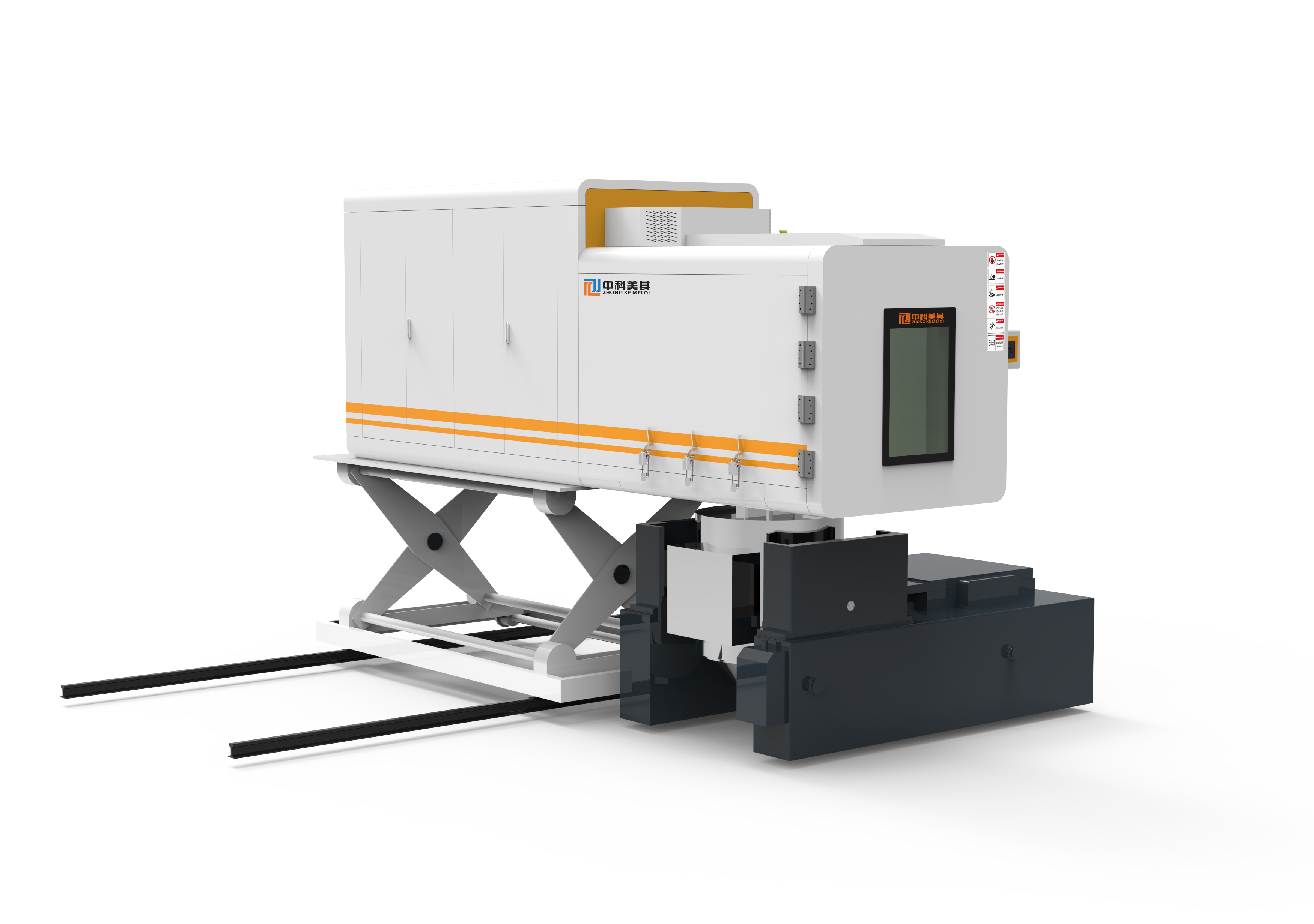

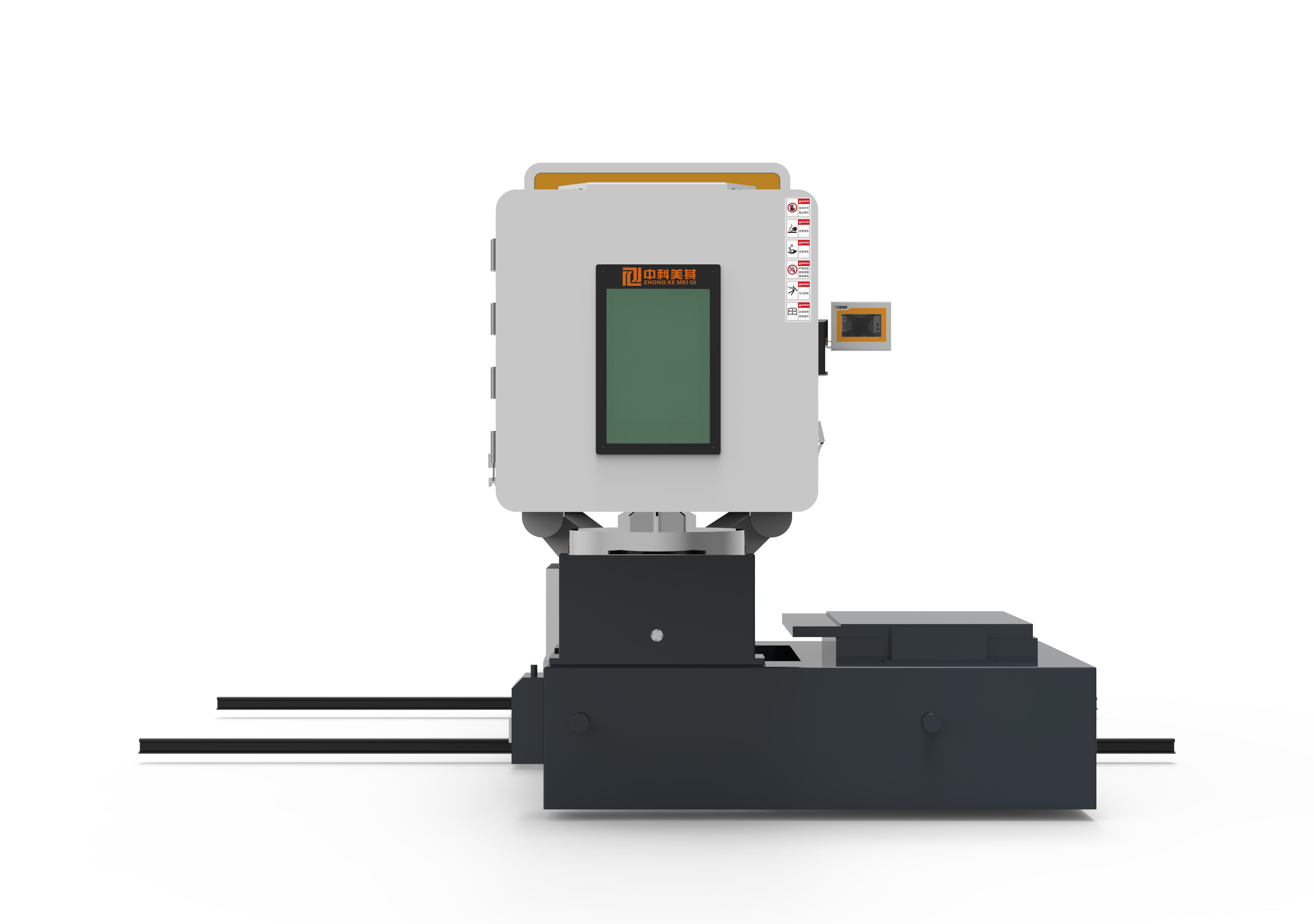

Model:MQ-THV1000

Temperature HUmidity Vibration Test Chamber

Temperature Humidity Vibration Test Chamber

Technical indicators

|

Product name |

Temperature and humidity vibration three comprehensive test chamber |

|||

|

Product model |

MQ-THV500 |

MQ-THV1000 |

MQ-THV2000 |

|

|

Nominal volume |

Unit/L |

500 |

1000 |

2000 |

|

Inner size |

Width × depth × height (mm) |

750×750×900 |

1000×1000×1000 |

1300×1300×1200 |

|

External size |

Width × depth × height (mm) |

950×2400×1950 |

1200×2600×2150 |

1500×3500×2400 |

|

Performance index |

temperature range |

A,-40℃~150℃ B,-70℃~150℃ C,-90℃~150℃ |

||

|

Humidity range |

A,10%~98%RH B,20%~98%RH C, 30%~98%RH |

|||

|

Temperature fluctuation |

±0.5℃ |

|||

|

Humidity fluctuation |

≤±2%RH |

|||

|

Temperature uniformity |

≤±2.0℃ |

|||

|

Temperature deviation |

≤±2.0℃ |

|||

|

Humidity deviation |

Humidity>75%RH:≤+2,-3%RH; Humidity<75%RH:≤±5%RH |

|||

|

Heating rate |

2,5,10,15,20℃/ Min |

|||

|

Cooling rate |

2,5,10,15,20℃/ Min |

|||

|

Vibration frequency |

3~2500HZ;3~3000HZ;5~4500HZ; |

|||

|

Maximum acceleration |

500m/s2;700 m/s2;1000m/s2; |

|||

|

Maximum displacement |

25mm;51mm; |

|||

|

Table size |

φ320mm;φ445mm;φ550mm; |

|||

|

Refrigeration method |

Compressor refrigeration |

|||

|

Cooling method |

Air-cooled/water-cooled |

|||

|

Main components

|

Control System |

Siemens programmable controller + touch screen + independent development program |

||

|

Heating system |

Fully independent system, high efficiency stainless steel finned tube heater |

|||

|

Cooling System |

Importer-type scroll compressor |

|||

|

Circulatory system |

Temperature and low noise motor, stainless steel centrifugal impeller |

|||

|

Main materials |

Carton material |

High-quality carbon steel plate, phosphating electrostatic spray treatment |

||

|

Inner box material |

International standard SUS304# stainless steel mirror treatment |

|||

|

Insulation material |

Hard flame retardant polyurethane foam |

|||

|

Sealing material |

High and low temperature environment-friendly silicone rubber seal |

|||

|

Voltage |

380±10% VAC, 50Hz; 3L+N+G |

|||

|

Communication Interface |

RS232 communication interface, USB data interface |

|||

|

Standard configuration |

1 sample holder, 1 test lead hole, 1 movable bottom plate, 1 sealed bottom plate |

|||

|

Optional accessories |

Recorder, remote control software, insulated sample holder, split operator, dry air purge, |

|||

|

Safety devices |

Leakage, short circuit, motor overheating, heater overheating, humidification, water shortage, compressor overpressure, overload, multiple overtemperature protection |

|||

|

Environmental requirements |

Ambient temperature: 5 ~ 35 °C, relative humidity: ≤ 85% RH, no strong vibration, electromagnetic radiation, dust and corrosive substances around; |

|||

|

Note: 1.temperature performance parameters are in the ambient temperature of 25 °C, studio no load conditions, in accordance with GB/T5170.2-2008 test; 2. can be customized according to the specific requirements of the user non-standard three comprehensive high and low temperature test chamber; 3. This technical information is subject to change without notice. |

||||

Standard Compliance :

1.GB/T 10589-2008 :cryogenic test chamber technical conditions

2.GB/T 10592-2008 :high and low temperature test chamber technical conditions

3. IEC60068-2-1 Environmental testing - Part 2: Test methods - Tests A: Cold

4. IEC60068-2-2 Environmental testing for electric and electronic products Test methods - Tests B: Dry Heat

5. IEC60068-2-78 Environmental testing - Part 2-78: Tests -Test Cab: Damp heat ,steady state

6. IEC60068-2-30 Environmental testing for electric and electronic products - Part 2: Test method - Test Db: Damp heat, cyclic (12h+12h cycle)

7. IEC60068-2-14 Environmental testing for electric and electronic products-Part 2: Test Methods-Test N: Change of temperature

8. MIL-STD-810F-501.4 High temperature test

9. MIL-STD-810F-502.4 Low temperature test

10. MIL-STD-810F-507.4 Damp heat test

11.GJB 360B-2009: test methods for electronic and electrical components

12.JJF 1270-2010: calibration specification for temperature, humidity and vibration integrated environmental testing system

13.GB/T 5170.2-2008: test method for environmental test equipment of electric and electronic products Temperature test equipment