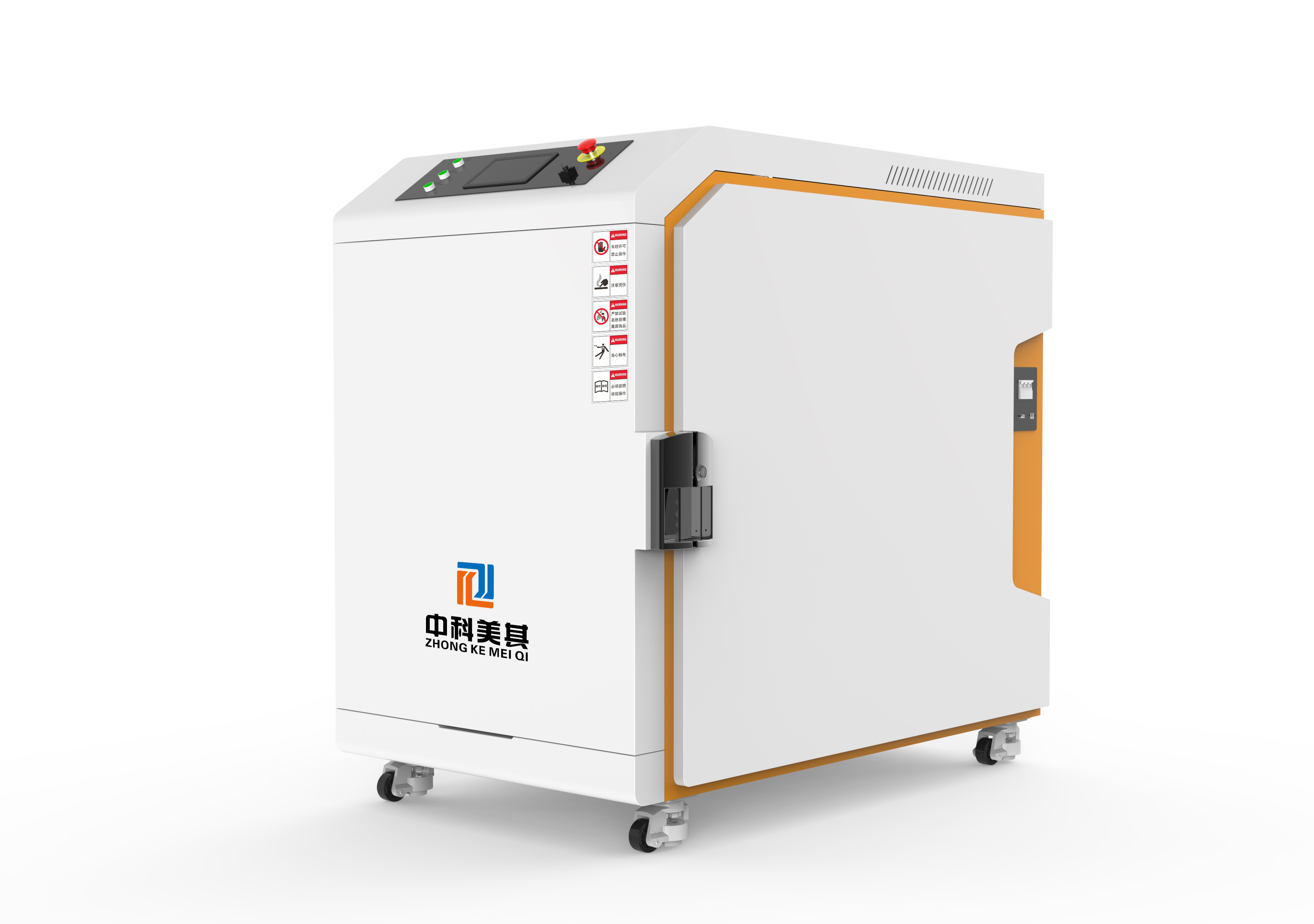

Model:MQ-HT100

High Temperature Test Chamber

1) High performance with low power consumption

2) Control System: SIEMENS PLC + Independent programming development design +touch screen

3) Refrigeration System: Single compressor refrigeration technology (PS : American COPELAND commercial scroll compressor . During the temperature control , only cooling no heating, and also no cooling during the heating, which can save more than 40% energy)

4) Humidity Control System: Independent patented technology, electric steam humidification --- High precision of collection and humidity control (Humidity sensor adopts imported electronic Finnish VAISALA)

5) Water Supply:

A. Manual--- the chamber is equipped with self-priming water pump

B. Automatic --- Water level control valve is installed at the rear of the chamber, and the water pipe interface is reserved.

High TemperatureTest Chamber

Technical Parameters

|

Product name |

high temperature test chamber |

|||||

|

Product model |

MQ-HT100 |

MQ-HT250 |

MQ-HT500 |

MQ-HT1000 |

||

|

Nominal volume |

unit/L |

100 |

250 |

500 |

1000 |

|

|

Inner size |

Width × depth × height (mm) |

450×450×500 |

600×600×700 |

700×800×900 |

1000×1000×1000 |

|

|

External size |

Width × depth × height (mm) |

790×770×900 |

860×920×1150 |

1050×1150×1300 |

1300×1350×1400 |

|

|

performance index |

Temperature range |

A、RT+20℃~250℃ B、RT+20℃~300℃ |

||||

|

Temperature fluctuation |

±0.5℃ |

|||||

|

Temperature uniformity |

≤±2.0℃ |

|||||

|

Temperature deviation |

≤±2.0℃ |

|||||

|

Heating rate |

≥3.0℃/ min |

|||||

|

Main components |

Control system |

SIEMENS programmable controller + touch screen + independent development program |

||||

|

Heating system |

Fully independent system, high efficiency stainless steel fin tube heater |

|||||

|

Sensor |

A PT100 |

|||||

|

Circulatory system |

High temperature and low noise motor, stainless steel centrifugal impeller |

|||||

|

Main materials |

External material |

High-quality carbon steel plate, phosphating electrostatic spray treatment |

||||

|

Internal material |

The mirror surface treatment of international standard SUS304 stainless steel plate |

|||||

|

Insulation material |

Superfine glass fiber |

|||||

|

Sealing material |

High temperature and environmental protection type silicone rubber seal strip |

|||||

|

Voltage |

220±10% VAC,50HZ,L+N+G |

380±10% VAC,3L+N+G |

||||

|

Communication interface |

RS232 communication interface and USB data interface |

|||||

|

Standard configuration |

1 sets of sample frames and 1 sets of test lead holes |

|||||

|

Self selected accessories |

Recorder, remote control software, insulating sample frame, and split operator |

|||||

|

Safety device |

Leakage, short circuit, motor overheating, heater overheating, multiple overtemperature protection |

|||||

|

Environmental requirements |

Ambient temperature: 5~35 degrees Celsius, relative humidity is less than or equal to 85%RH, no strong vibration, electromagnetic radiation, no dust and corrosive substances |

|||||

|

Note: 1. The temperature performance parameters are all at the ambient temperature of 25 degrees C, and under the condition of no load in the studio, the test is based on GB/T5170.2-2008. 2. The non - standard high temperature test chamber can be made in accordance with the specific requirements of the user. 3. This technical information is subject to change without notice. |

||||||

Standard Compliance:

1. IEC60068-2-2 Environmental testing for electric and electronic products Test methods -

Tests B: Dry Heat

2.MIL-STD-810F-501.4 High temperature test

3.GB/T 11158-2008: high temperature test chamber technical conditions

4.GB/T 5170.2-2008: electrical and electronic products environmental test equipment test methods